HL230 AC Motor Drive Wheel features 1.6-2.2kW AC induction motors with 22.07:1 gear reduction, delivering 100m/min speed and 1200kg capacity. Available in multiple reduction ratios (14.5-27.31), its φ230x75mm polyurethane/rubber wheels provide 2500N max traction for heavy-duty AGVs and material handling equipment.

| Main performance parameter | |||

| Model | HL230-AC1600-24-22B | HL230-AC2200-24-22B | |

| perfomance index | Parameter | parameter | |

| Travel motor | Motor type | AC induction motor | AC induction motor |

| Motor power KW | 1.6 | 2.2 | |

| Voltage V | 24 | 24 | |

| Rated current A | 78 | 105 | |

| Rated torque Nm | 5.66 | 6.26 | |

| Rated speed r/min | 2560 | 3352 | |

| Encorder type | Pulse type | Pulse type | |

| Gearbox | Reducer type | Secondary gear reduction | Secondary gear reduction |

| Reducer ratio | 22.07:1 | 22.07:1 | |

| Brake | Brake torque Nm | 16 | 16 |

| Rated Voltage | DC24 | DC24 | |

| Wheel | Tyer material | Polyurethane/Rubber | Polyurethane/Rubber |

| Wheel size | φ230X75 | φ230X75 | |

| Other | Steering limit angle | None | None |

| Travel speed m/min | 0-100 | 0-100 | |

| Rated traction N | 1000 | 1080 | |

| Maximum traction N | 2500 | 2700 | |

| Carrying capacity Kg | 1200 | 1200 | |

| Net weight Kg | 58 | 60 | |

Voltage optional : DC 24V Reduction ratio optional :14.5,16.7,22.07 27.31 Used for mobile robots (AGV), pallet stackers, pallet trucks, sweepers, aerial work trucks, etc. | |||

Motor & Gear Details

AC induction motor with either 1.6 kW or 2.2 kW power for the two model variants (HL230-AC1600-24-22B and HL230-AC2200-24-22B).

Rated motor speeds around 2 560 rpm (for 1.6 kW) or 3 352 rpm (for 2.2 kW) respectively.

Gear reduction (secondary gear) – the default ratio is 22.07:1, with optional ratios of 14.5:1, 16.7:1, 22.07:1 and 27.31:1.

Wheel & Tyre

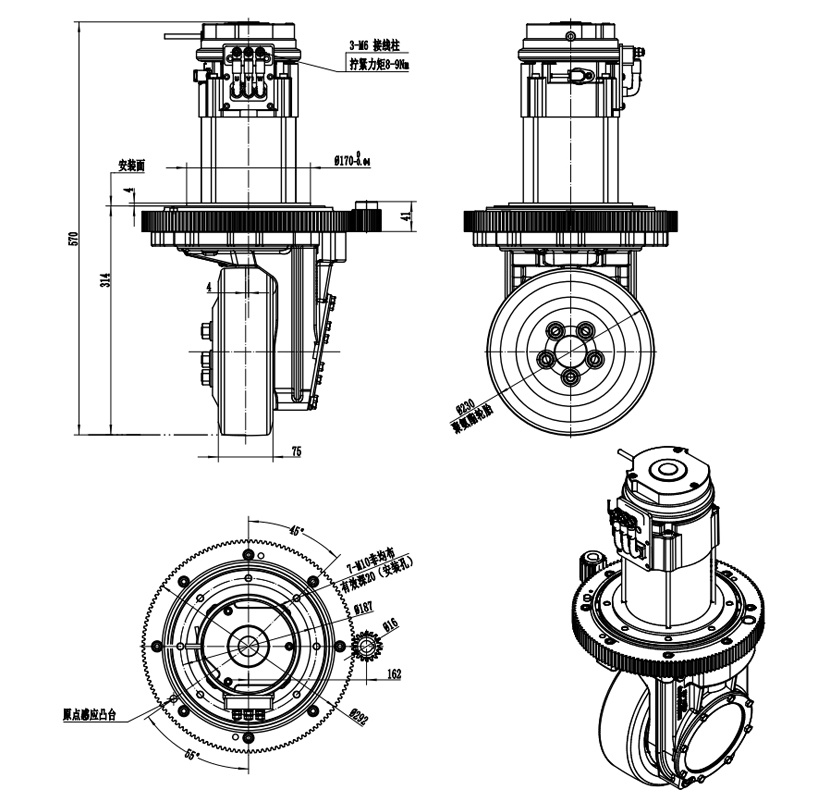

Wheel size: φ230 × 75 mm, with tyre material: polyurethane / rubber.

Designed for vertical drive configuration (the “Vertical Drive Wheel” category) though the naming here indicates AC motor drive wheel.

Performance / Capability

Travel speed: 0–100 m/min.

Rated traction: ~1 000 N (1.6 kW model) or ~1 080 N (2.2 kW model)

Maximum traction: up to ~2,500 N (1.6 kW) or ~2,700 N (2.2 kW)

Carrying capacity: 1,200 kg (per unit) for both models.

Brake & Electrical

Brake torque: 16 Nm, rated voltage for brake DC 24 V.

Input/voltage for motor: 24 V (DC bus) is the listed standard.

Application Domain

Suitable for mobile robots (AGVs), pallet stackers, pallet trucks, sweepers, aerial work trucks, etc.

Optional Customization

Reduction ratio optional (as noted above) to fit various speed/torque trade-offs.

From the above features, here are the advantages this product offers in practical deployment:

High Load & Traction Capability: With a rated carrying capacity of 1,200 kg and potential traction up to ~2,700 N, the HL230 is well-suited for relatively heavy duty applications in AGVs or material handling equipment, giving robustness for moderately heavy loads compared to lighter drive wheels.

Good Speed Range: Travel speed up to 100 m/min gives good throughput for many indoor logistics or factory automation tasks. The combination of motor power + gear reduction means you can match speed vs torque for your application.

Flexibility via Gear Ratios: The optional reduction ratios allow designers to tailor for higher speed or higher torque depending on the load/drive scenario — offering a configurable platform rather than one fixed spec.

Durable Tyre & Design for Industrial Environments: Tyre material (polyurethane/rubber) offers a good mix of grip, durability and shock absorption. The wheel size φ230 × 75 mm is substantial and designed to handle heavier loads with stability.

Integrated Brake & Reliable Drive System: A built-in brake (16 Nm) at DC 24 V allows the wheel to hold position securely when required (important in AGV stop/hold scenarios). The AC motor + gearbox arrangement implies a matured mechanical drive design for industrial use.

Simplified Integration for AGVs & Robots: Since the product is targeted at AGVs, pallet stackers, sweepers etc., it likely supports standard mounting/drive brackets and interfaces, allowing system integrators to more easily adopt it.

Space-efficient Vertical Drive Option: Being a vertical drive wheel (designed to drive vertically mounted wheel units) helps when space is constrained or for underbody drives where lateral room is limited.

Durability & Reliability: The AC induction motor + gear reduction design tends to be robust, implies fewer maintenance issues (less wear than some belt or chain drives) and is more suitable for continuous industrial use.

Contact us for a drive system solution for your AGV.

Tel:

E-mail:

Address:

No. 17, Jingwu Road, Pingdu Economic Development Zone, Qingdao, Shandong 266700, China.