Special industry custom-made steering wheels, with the overall protection level IP54; using low-voltage servo system, supporting various control methods such as CAN, Modbus, EtherCAT buses, and pulses; the specially designed mechanical structure has the characteristics of suitable installation height and extremely small rotation radius; the external brake and easily detachable wheel design also have the characteristics of reliable structure, low heat generation, low failure rate, and easy maintenance.

| Main performance parameter | ||

| Model | HW155-SM400-48-JD-C | |

| perfomance index | Parameter | |

| Travel motor | Motor type | Permanent magnet synchronous servo motor |

| Motor power KW | 0.4 | |

| Voltage V | 48 | |

| Rated current A | 10.1 | |

| Rated torque Nm | 1.27 | |

| Rated speed r/min | 3000 | |

| Encorder type | Incrmental encorder | |

| Gearbox | Reducer type | Secondary gear reduction |

| Reducer ratio | 45.5:1 | |

| Brake | Brake torque Nm | 4 |

| Rated Voltage | DC24 | |

| Wheel | Tyer material | Polyurethane/Rubber |

| Wheel size | φ155X55 | |

| Steering part | Motor type | Permanentmagnet synchronous servo motor |

| Motor power KW | 0.2 | |

| Voltage V | 48 | |

| Rated current A | 5.1 | |

| Rated torque Nm | 0.64 | |

| Rated speed r/min | 3000 | |

| Reducer type | Secondary gear reduction | |

| Reduction ratio | 138.6:1 | |

| Encorder type | Incrmental encorder/Absolute encoder | |

| Other | Steering limit angle | ±130° |

| Travel speed m/min | 0-32 | |

| Rated traction N | 670 | |

| Carrying capacity Kg | 300 | |

| Net weight Kg | 29 | |

| Used for mobile robots (AGV), pallet stackers, pallet trucks, sweepers, aerial work trucks, etc. | ||

Overall Protection Level: IP54

The assembly is rated to IP54, meaning it is protected against dust ingress (limited) and splashing water from any direction.

Supports Multiple Control Interfaces / Protocols

It can work with control methods such as CAN, Modbus, EtherCAT, and pulse control.

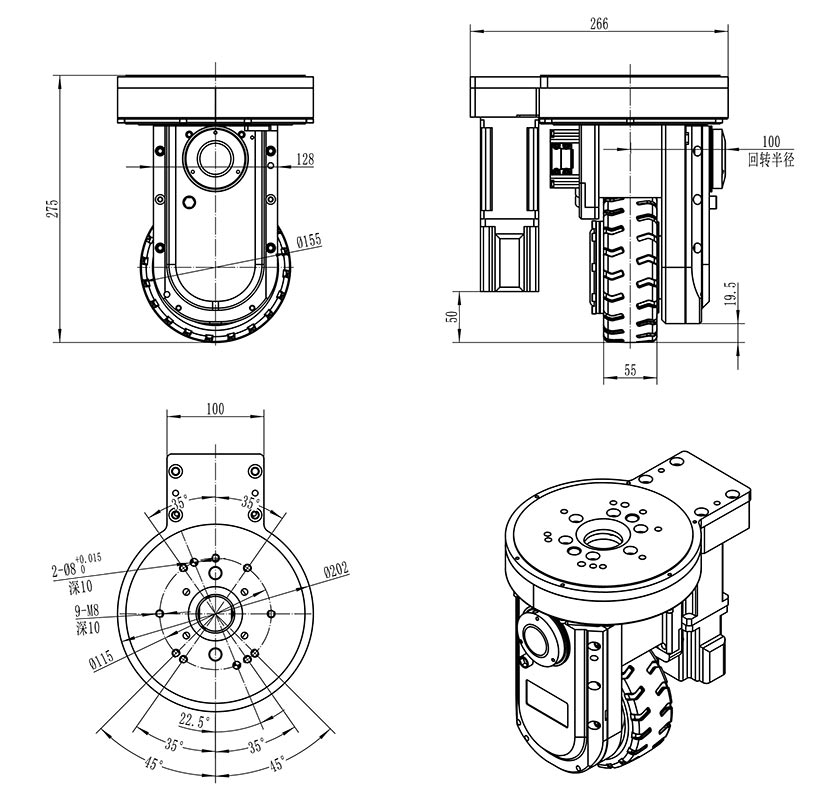

Compact Mechanical Design / Small Turning Radius

The mechanical structure is optimized for low installation height and a very small rotation radius, which helps in tight-space maneuvering.

External Brake & Detachable Wheel Design

It includes an external brake, and the wheel is designed to be detachable, facilitating maintenance and reliability.

Low Heat Generation, Low Failure Rate

The design aims to reduce heat buildup and minimize failure points.

Performance Specifications (Travel & Steering)

Travel motor: permanent magnet synchronous servo motor, 0.4 kW at 48 V, rated speed 3000 rpm.

Gear reduction: 45.5:1 for drive.

Brake torque: 4 Nm.

Wheel tyre: polyurethane / rubber material; size Ø155 × 55 mm.

Steering motor: 0.2 kW, 48 V, with 138.6:1 reduction, steering limit ±130°.

Travel speed: 0–32 m/min.

Rated traction: 670 N.

Carrying capacity: 300 kg.

Net weight: 29 kg.

Intended Application Range

It is designed for use in mobile robots (AGVs), pallet stackers, pallet trucks, sweepers, aerial work trucks, etc.

From those features, here are the advantages or benefits that a user (robot designer, integrator, operator) can expect:

| Feature | Advantages |

IP54 protection | Provides moderate protection against dust and water — suitable for many industrial environments (though not for full exposure to water jets or deep immersion) |

Multi-protocol support (CAN, Modbus, EtherCAT, pulses) | Flexible integration into different control architectures; easier to interface with various automation systems |

Compact design & small turn radius | Good for tight spatial constraints; more maneuverability in narrow aisles or compact equipment |

External brake + detachable wheel | Easier maintenance — you can replace or service the wheel or brake without disassembling the entire unit |

Low heat generation & low failure rate | Improves reliability and durability; less downtime, longer service life |

High traction & decent payload | With 300 kg carrying capacity and 670 N traction, it can handle moderate loads while maintaining grip |

Speed range suitable for industrial AGVs | Travel speed up to 32 m/min is adequate for many warehouse / factory automation tasks |

Steering flexibility (±130°) | Versatility in steering allows sharper turns, better agility |

Material of tyre (PU / rubber) | Good balance of durability, grip, shock absorption, and lower noise vs hard material |

Contact us for a drive system solution for your AGV.

Tel:

E-mail:

Address:

No. 17, Jingwu Road, Pingdu Economic Development Zone, Qingdao, Shandong 266700, China.